Plastic Business

From our original brand items to OEM products, we have a versatile line up of plastic items covering a variety of product categories. We carry not only our own brand items, but perform OEM production for household storage, electronics, office, and construction- related products, in addition to other special order products. The processes of planning, design and drafting, manufacture, and sale are all handled in- house.

Product Introduction

Interior/Storage Products

Drawer Type Storage

Lidded Storage

Multilevel Storage

Small Accessory Storage

Stationery

Open Boxes

Specialized Storage

Multipurpose Storage

DIY/ Leisure Products

JEJ Astage products fit in with your many lifestyle scenes.

DIY

Leisure

Stationery

Gardening

Winter Items

Flow from product planning to delivery

Planning

Product planning may take the form of a product suggestion or recommendation from JEJ Astage just as much as it may take the form of a request from a retail partner. JEJ Astage acts as an "antenna", carefully observing market trends and trends in consumer lifestyles. Regardless of the type of the product, we ask ourselves, "What kind of product should we make?" and "Where would we use this product?" as we devise a product that fits the needs of consumers and the market.

Product Layout

The product blueprints are created at this stage through the use of CAD software. A 2D blueprint is created with the initial size and construction of the new product, with the final details and design finalized in the 3D blueprint. After the completion of the 3D blueprint, the 2D blueprint is adjusted to include more detail and solidify the design. At this stage, naming for the product is also considered.

Mold Construction

At this step, the blueprints for the mold are created by the mold builder, based upon the product blueprints. The mold is constructed so that even the product's fine details can be recreated in mass production.

Test Production

After setting the mold in the injection molding machine, we perform a test production. After confirming there are no issues related to product quality and safety via repeated test productions, we then prepare the mold for use in mass production.

Packaging Materia

Once the product's overall form is completed, the materials that will be the "face" of the product are designed. This includes the packaging design, labels, POP, and other materials. Creating materials that clearly convey the product's strengths is the key. We often consult with professionals in the packaging design industry for advice and new ideas to improve packaging design and add value to the product.

Mass Production

The product is molded with the new mold inside the injection molding machine. Parts are regularly checked by Quality Control and factory floor staff throughout the injection molding process. Only parts that have passed our rigorous check are allowed for use in the assembly and packaging of the final product that will then be sent to the customer.

Assembly/Packaging

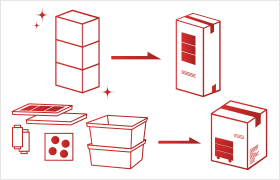

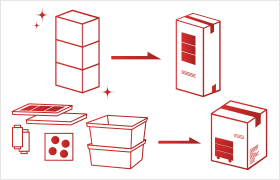

JEJ Astage products can be roughly divided into two types; ""pre- assembled"" and ""assembly required"".Pre- assembled products, which can be used immediately by the consumer upon unpacking, are assembled by JEJ Astage factory staff. This process includes not only the assembly of the product itself, but the application of all necessary stickers, labels, and other materials used in the final packaging of the item. Assembly required products, as the name might indicate, are products that must be either fully or partially assembled by the consumer upon unpacking. Products are packaged in parts, which allows for more compact packaging sizes. Regardless of the product type, once final packaging has been completed, the packaged products are loaded onto pallets in pre- determined quantities that are efficient for storing until shipment.

Shipping

The products are loaded onto a cargo truck, and are shipped to retail stores, trading companies, and warehouses.

Online Catalog

Inquiry/

Quotation Request

Please feel free to get in touch with us with any of your questions.